Boiler scale is a hard, insulating deposit that forms on water-side surfaces of steam boilers when minerals in feedwater precipitate out under heat and pressure. As water is heated into steam, dissolved calcium, magnesium (from hard water), silica, and other impurities crystallize and cling to boiler tubes and drums. Over time these layers thicken, acting like insulation between the hot fire and the water. Even an “eggshell-thin” film of mineral scale (about 1/32″ thick) can cut thermal efficiency by 2–7%.

As shown above, heavy scale buildup can coat the entire interior of boiler tubes. Such deposits form because hard water chemistry (high hardness, alkalinity or dissolved solids) leads to precipitation of Ca/Mg salts on hot metal. When the water-side surfaces are coated with scale, the boiler must burn more fuel to achieve the same steam output. In fact, industry data confirm that scale dramatically drives up fuel use: for example, a mere 1/16″ of scale can cut boiler efficiency by over 12%, causing plants to spend double-digit percentages more on fuel. Over time these costs – plus increased wear and tear – add up. According to one study, even thin scale can raise annual fuel costs substantially, and heavy scaling in a large facility can translate into six-figure losses or more.

Facilities with robust maintenance programs avoid scale issues more effectively. Continuous improvement is key – for instance, many plants now use online hardness analyzers or send periodic samples to specialized labs for detailed ion profiles. Any sign of drifting hardness or pH should prompt immediate corrective action.

Miura Canada’s Water Treatment and Monitoring Solutions

Chemical Treatments - Miura's Boilermate

BOILERMATE® 1200S is Miura’s all-in-one boiler water treatment. It’s a silica-based product that creates a protective layer of film on the water tube surface to protect against corrosion. It also includes a small dosage of scale dispersant that safeguards against the minute amount of hardness that conventionally leaks out of a water softener. BM1200S effectively treats hardness if used in a system with an active and effective water softener – i.e., BM1200S is not intended to handle large concentrations of hardness.

Hardness Detection

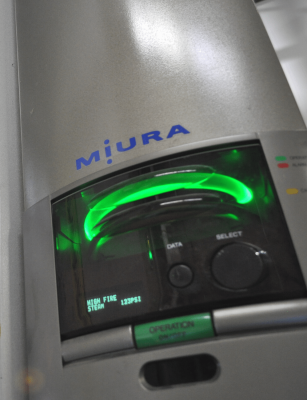

Miura’s Colorimetry Hardness Detection System is designed to actively prevent scale buildup by continuously monitoring boiler water quality. Fully integrated into the boiler’s control panel, this system works like a “metal detector” for hardness—automatically injecting and mixing a reagent into the water and analyzing the results in real-time. The findings are displayed on a digital screen, giving operators instant insight into water conditions and helping to detect potential scaling before it becomes an issue.

Control and Monitoring

Miura’s BOILERMATE® Chemical Monitoring System works together with the BL Micro Controller and Miura Online Maintenance (MOM) to regulate the amounts of chemicals being administered to help prevent the overuse of the products.

Each Miura boiler also comes fitted with a BL Micro Controller, a boiler control interface that allows operators to navigate the boiler control panel and, among other things, monitor the surface temperature of the water inside the boiler tubes for early scale build-up detection. Rising temperatures signal that scale formation in the boiler tubes needs the operator’s attention.

Scale formation in a steam boiler is both common and preventable. With the proper controls and measures in place, you can protect the inside of your pressure vessel, prevent any unnecessary and costly downtimes, maintain operational efficiency, and ensure the ongoing safety of your boiler room.

Get expert advice on sizing your boiler room

Founded in Japan in 1927, Miura Boilers has grown to be one of the largest industrial steam boiler manufacturers in the world. Miura Canada has been manufacturing boilers for North America since 1987 and has a team of experts who can help you with all your boiler room needs.