How to Prolong the Lifespan of Your Boiler: Preventive Maintenance for Industrial Boilers

Industrial steam boilers are critical assets that represent a major investment for any facility. In fact, most industrial boilers are built to last 15–25 years on average, with 25 years being achievable on the high end when well-maintained. The key to reaching the upper end of that lifespan (and even beyond) is preventive maintenance – a proactive approach to care that ensures safety, efficiency, and reliability over the long term. Neglecting maintenance can lead to dangerous failures or inefficiencies, whereas a well-maintained boiler will run more efficiently, last longer, and experience fewer accidents or unplanned shutdowns.

In this blog, we’ll dive into general best practices for extending your boiler’s life. We’ll cover regular inspections, water quality control, blowdown procedures, timely parts replacement, and the use of modern tools like online monitoring. By following these practices, you can improve your steam boiler reliability and keep your system running optimally for years to come. And as you’ll see toward the end, partnering with experienced professionals can provide an extra layer of support to maximize uptime and safety.

The Importance of Preventive Maintenance for Boiler Lifespan

Preventive maintenance is all about addressing issues before they escalate. This approach yields numerous benefits for boiler owners and operators:

-

Safety: High-pressure steam boilers can pose significant safety risks if not properly maintained. Regular maintenance ensures safety devices (like relief valves and low-water cutoffs) function correctly, greatly reducing the risk of explosions or accidents.

-

Efficiency: Over time, soot and scale buildup on boiler surfaces force the boiler to burn more fuel for the same steam output. Maintenance tasks like cleaning and water treatment keep the boiler running at peak efficiency, saving fuel and money. Even a thin layer of scale (as little as 1/8″) can cause a 20–25% loss in efficiency, so removing deposits is critical.

-

Longevity: Simply put, regular maintenance can significantly extend the lifespan of a boiler. By finding and fixing minor issues early, you prevent them from causing major damage that could necessitate costly repairs or even early replacement. The better you maintain your boiler, the longer it will last.

-

Reliability and Uptime: A boiler that is cared for is far less likely to break down unexpectedly. In industrial settings, an unplanned boiler outage can halt production. Preventive maintenance improves steam boiler reliability, ensuring you have a steady supply of steam and minimizing downtime.

-

Regulatory Compliance: In Canada and elsewhere, boilers are subject to strict safety and environmental regulations. Annual inspections by certified inspectors are often mandated.

-

Cost Savings: While maintenance has a cost, it is usually far less than the expense of emergency repairs, fuel wastage, or a catastrophic failure. Proactive care means fewer costly surprises.

Regular Inspections

Frequent inspections are the cornerstone of boiler longevity. By regularly examining your boiler’s condition, you can catch wear-and-tear issues early and keep the system running safely.

Daily/Weekly Walkdowns

Safety Device

Operational Inspections

Scheduled Professional Inspections

Thickness testing

Online Monitoring and Smart Controls

In today’s digital age, one of the most powerful tools for extending equipment life is real-time monitoring and analytics. Here’s why embracing these technologies boosts reliability and lifespan:

Real-Time Data & Alerts – Connected monitoring platforms continuously gather data on key parameters – pressure, temperature, water level, fuel flow, exhaust conditions, water quality metrics, and more. Early warning of conditions like high vibration, creeping pressure, or abnormal cycling can prompt maintenance actions that prevent damage. With Miura Connect, you gain remote access to critical water quality indicators and automated alerts that make it easier than ever to stay ahead of scale buildup and corrosion.

Trend Analysis and Predictive Insights – Over weeks and months, you can observe trends in boiler performance – for instance, a slow decline in efficiency or a gradual increase in water usage. These trends are invaluable for predictive maintenance. They enable you to schedule service before a minor issue becomes a major outage. With Miura Online Maintenance (MOM), you get access to detailed operational data, trend tracking, and predictive analytics that identify potential issues before they cause downtime. This proactive approach helps you extend boiler life and avoid costly surprises.

Remote Expert Support – One of the game-changing aspects of advanced monitoring like Miura’s Internet MOM is the ability for remote technicians to directly see what’s happening in your boiler. Miura’s dedicated service team, for instance, can remotely monitor all your connected boilers 24/7 in real time

Water Quality Management (Feedwater Treatment & Monitoring)

One of the silent killers of boilers is poor water quality. Hard water, dissolved oxygen, and other impurities in the feedwater can lead to devastating problems like scale formation and corrosion inside the boiler. Over time, these issues will reduce efficiency and can cause premature boiler failure.

Implement a Water Treatment Program – Proper water treatment is one of the most critical steps in protecting your boiler from scale, corrosion, and premature wear. By maintaining consistent water quality, you can maximize heat transfer efficiency and reduce maintenance frequency. Miura’s Boilermate treatment solution works in harmony with our water softeners to provide comprehensive protection—keeping your system clean, efficient, and built to last.

Prevent Scale and Corrosion – One of the silent killers of boilers is poor water quality. Hard water, dissolved oxygen, and other impurities in the feedwater can lead to devastating problems like scale formation and corrosion inside the boiler. Over time, these issues will reduce efficiency and can cause premature boiler failure.

Routine Blowdown – Carrying on from water quality, blowdown is the practice of deliberately removing a portion of the boiler’s water to flush out impurities. This simple maintenance task has a big impact on boiler health. Regular blowdown prevents the accumulation of dissolved solids and sludge that can lead to scale, corrosion, and unstable water levels.

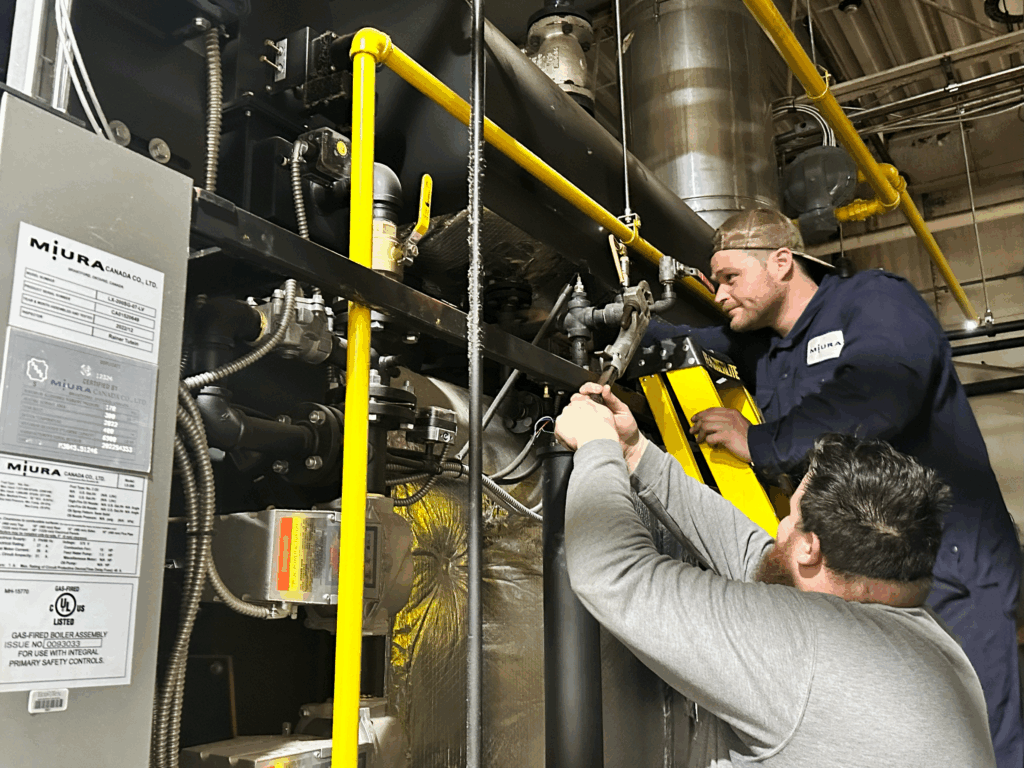

Expert Support and Maintenance

Even the best internal maintenance program can benefit from the guidance of experts. Miura Canada have built their business around helping facilities keep their boilers in top shape through comprehensive maintenance services. By enrolling in a professional maintenance plan like BMC or MIC+MOM, you gain access to specialized knowledge, routine service visits, and water treatment solutions.

Qualified Technicians and Routine Service

Preventative Maintenance Plans: Miura Canada offers tiered maintenance plans (such as their MIC+MOM, BMC, and MMP+ contracts) that are tailored to different operational needs – know more here.

Expert Analysis and Continuous Improvement

Emergency Support and Fast Response

Get expert advice on sizing your boiler room

Founded in Japan in 1927, Miura Boilers has grown to be one of the largest industrial steam boiler manufacturers in the world. Miura Canada has been manufacturing boilers for North America since 1987 and has a team of experts who can help you with all your boiler room needs.