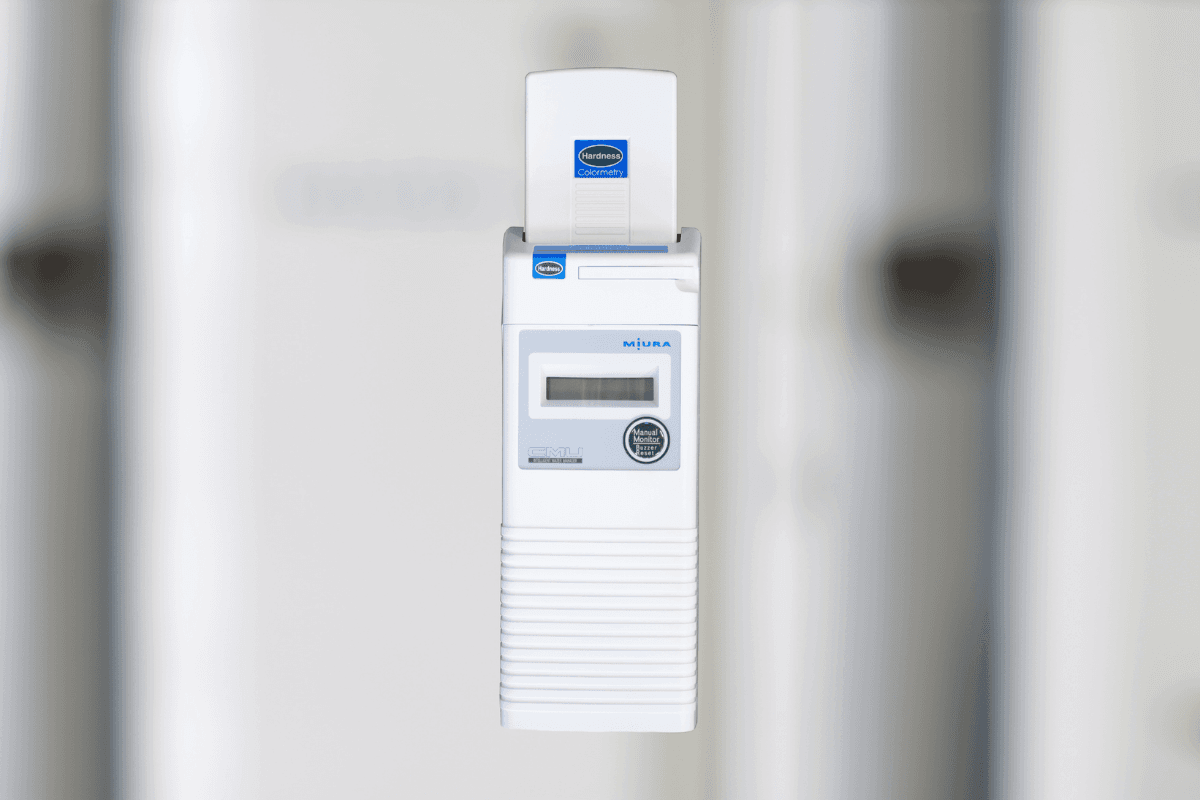

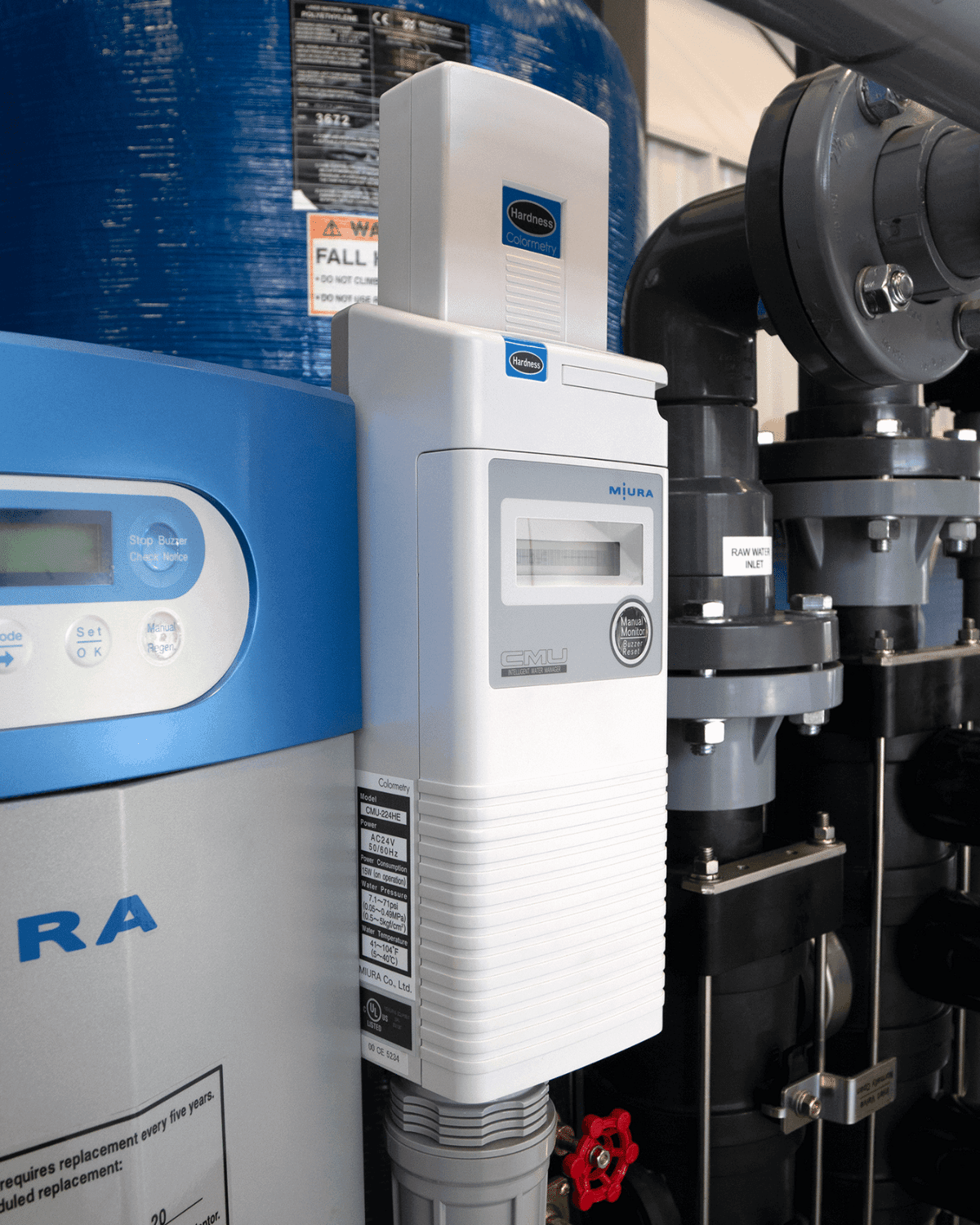

Colormetry

MIURA’s Colormetry CMU-324HE is a hardness detection device that utilizes colorimetric analysis to monitor ionic concentration in pre-treated soft water. Miura’s Colormetry Hardness Detector solves problems of incorrect readings and time-consuming manual checks by sampling the system’s softened water and testing for the presence of harmful contaminants that should have been removed by the softener system. If hardness is detected as a result, the colormetry unit visually and audibly alerts the boiler operator and signals a caution or an alarm offering so the system can address the issue with automated reagent injection, mixing, and evaluation integrated into the boiler control system.

Share

Colormetry Features

Automated Scheduled Testing

Periodically samples softened water, and performs colorimetric analysis to determine hardness concentration. These timed increments can be set from every 30 minutes to every 240 minutes

Communication

Communicates testing results with Miura components or building automation system to alert operators of a problem and to initiate countermeasures. When a Miura boiler receives a hardness caution, the boiler responds by temporarily increasing the surface blowdown to prevent scale formation.

Signals Softener Regeneration

If hardness leakage is detected, the Colormetry unit can signal the MW-U softener to start regenerating. Utilizing its dual-tank design, the active and idle tanks will swap, providing the boiler system with soft water once again. Then, the leaking tank will be regenerated via a saline wash to replenish the softener resin’s effectiveness.

Easy-to-replace Cartridges and Filters

When the reagent cartridge reaches low capacity, the cartridge status light will illuminate signaling a replacement is needed. Simply release the cartridge lock, pull out depleted cartridge, insert new cartridge and close lock to continue normal testing operations.

Self-Calibrating

The Colormetry unit performs a true-zero test before every automated sampling. This saves valuable boiler operator time and ensures accurate results from every test.

Alarm and Fault History Logging

When an alarm or caution is signaled, the Colormetry unit displays the alarm fault codes that assist the operator in resolving the problem and sends fault code information to the Miura Online Maintenance (MOM) program. Up to five previous cautions or alarms are stored for operator reference.